SensorZone is the market-leading Proximity Warning System that helps prevent worksite collisions and promote safe behavior among employees and contractors. This system has been proven to help reduce collisions between people and heavy machinery in a variety of sectors, such as construction, waste management, ports, and warehousing. SensorZone is a life-saving technology specifically designed to alert personnel of their proximity to a machine, helping to reduce the number of injuries and fatalities on the job.

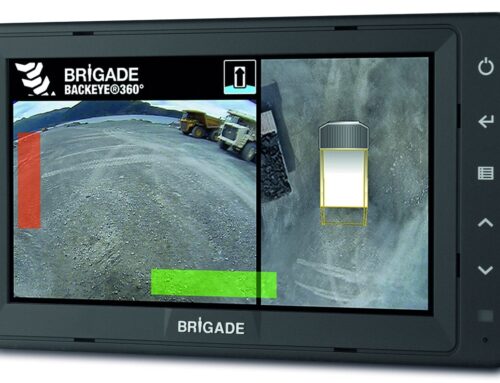

The U.S. health and safety regulator, OSHA, identified ‘collision with’ and ‘being caught between’ machines as two of the four main causes of injury/fatalities on construction sites. With the prevalence of heavy machinery on worksites comes the potential for fatal collisions if personnel are unaware of their location in relation to the machine’s movements. The SensorZone system eliminates this risk by placing a configurable virtual detection zone around a machine. The system triggers an instant “Triple alert” (visual, audible and physical) alarm if a zone is breached by someone wearing a tag, thus alerting them of their proximity to the machine.

The wearable personal tags are anti-tamper, maintenance free and have a working battery life of over 3 years and are designed to be tested at the start and end of each shift at a simple Tag Test unit. The use of the site “Area Shield” can create safe zones where false alerts won’t happen and “Smart Bubble” technologies shrink the safety zone around a machine when it is safe to do so like when the machine is not in use. All activity is recorded allowing proactive management of company safety practices and detailed real-time analytics in case of an accident.

SensorZone prioritizes speed and ease of installation, without comprising on quality. The system is designed to be installed in just one hour or even faster for vehicles that visit a site temporarily. It uses the onboard 12/24V supply and is mounted using magnetic or suction mounts, meaning no permanent modification needs to be made to the machine.

Implementing the SensorZone Insight Platform brings numerous operational benefits. Improved training programs can be developed based on the data insights, ensuring that employees are equipped with the right knowledge and skills to perform their tasks safely. Moreover, the platform helps identify danger areas or “hot spots” within worksites, allowing companies to modify site designs and work patterns accordingly, ultimately reducing the risk of accidents.

VISUAL

A combination of external beacons and internal LEDs

AUDIBLE

Sound alerts on the machine and tag

PHYSICAL

Vibrations from the tag

According to the U.S. Bureau of Labor Statistics, there were 6,110 non-fatal workplace injuries due to being struck by a moving machine in 2020. The average day’s absence for an employee involved in a non-fatal injury is 32 days, according to the Electronic Library of Construction Occupational Safety & Health. These statistics demonstrate the importance of having a safety system such as SensorZone in place to prevent the potential for catastrophic injuries and fatalities.

The SensorZone system is a highly effective solution for increasing safety in a range of worksites, from construction to ports. It alerts personnel when they are in danger of being struck by a machine, helping to reduce the number of injuries and fatalities in the workplace. The system is designed to be installed quickly and easily, without any additional downtime or disruption to the worksite. With SensorZone, organizations can create a safe working environment and ensure the safety of their employees and contractors.