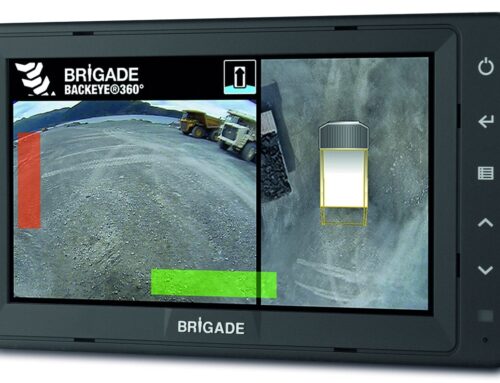

Recent advancements in technology have dramatically improved heavy equipment collision warning systems. With a typical safety camera system, the operator must remember to look at the screen before turning or backing the equipment. If they don’t look or don’t see an object or person in their path, the chances of a severe accident and lost time are significant. Active safety systems like proximity sensors alert the operator to an object’s presence in the machine’s path. Unfortunately, these systems cannot differentiate between a truck, a pile of dirt or a person. Frequent false alerts reduce productivity and cause some operators to ignore these warnings, often with drastic consequences.

Correct-Ai PROX-EYE Detection System

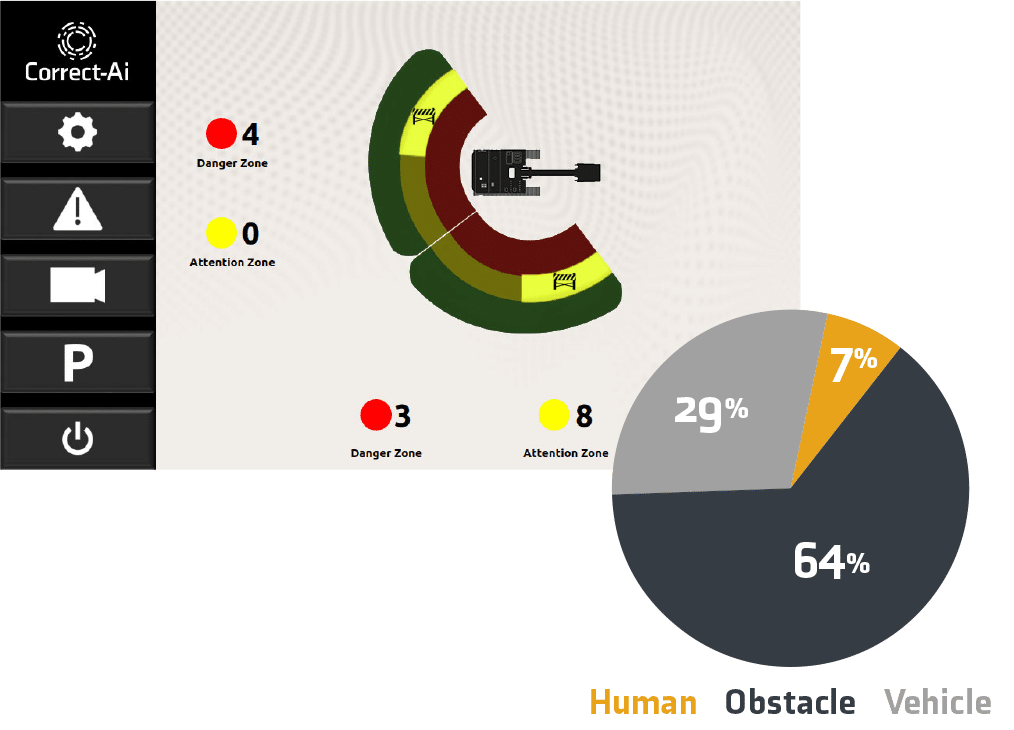

Correct-Ai is a Canadian company that has developed a unique object detection solution that utilizes artificial intelligence software with optical and LIDAR sensors to assist heavy equipment operators in monitoring risks. Their PROX-EYE Proximity Detection System can identify over 6500 objects and calculate the distance to a person, an obstacle or a vehicle. PROX-EYE systems use AI-driven hazard assessment processing to alert the operator when needed while dramatically reducing nuisance alarms. Imagine the benefits of each piece of equipment having dedicated spotters that always stay alert and focused.

Unparalleled Accident-Prevention Technology

The Certified Commercial & Fleet Services team is excited to add Correct-Ai’s PROX-EYE technology to our suite of heavy-equipment solutions. Their artificial intelligence processing will dramatically reduce accidents. By combining Correct-Ai’s exclusive technologies with our experience in designing and implementing accident prevention and productivity-enhancing solutions, Certified Commercial & Fleet Services can help our clients operate more efficiently.

Correct-Ai’s solutions include the AI-equipped PROX-EYE Reverse that is designed for heavy equipment while backing up to the PROX-EYE Stereo dual-camera and PROX-EYE Dual LIDAR-equipped systems for challenging worksites, like mining, pipeline, construction, and industrial applications. In addition, the PROX-EYE solid-state recorder provides data collection, detailing risk reporting with time-stamped events and high-resolution screen captures. This data information allows safety personnel and site superintendents to assess event data for educational purposes or incident investigation.

Risk Monitoring

Award-Winning Technology

The Canadian Energy Pipeline Association (CEPA) recognized Correct-Ai’s PROX-EYE Vision Guidance System with its prestigious 2022 Innovation Award. CEPA noted that this exclusive technology prevents accidents in real-time and can be used to identify future risks. In addition, the unprecedented efficiency of PROX-EYE minimizes productivity disruptions while saving lives and preventing equipment damage. Most importantly, these systems reduce the need to rely exclusively on the operator to monitor the work or travel area.

Case Study – Pipeline Weld Shack

Proper pipeline welding requires careful environmental control. As such, portable weld shacks have become a staple in the industry. These small portable buildings protect the welders, their equipment and the actual welding process from wind, rain and other contaminants that could affect the quality and reliability of the weld. Once a connection is complete, the shack must be vacated, and a crane moves it to the following site, where the next joint will be made. Ensuring all staff members are out of the shack is a top priority before the move begins. A simple check-in and check-out process helped, but operator error and simple forgetfulness prevented perfect compliance. The company building the pipeline turned to Correct-Ai for a foolproof way to ensure there were no welders or staff in the shack before it was moved. Correct-Ai implemented their camera-based Artificial Intelligence solution to monitor the shack’s interior to ensure it was unoccupied before each move. The project involved training the system to recognize people using thousands of photos of men and women in different clothing. The system includes a motion detection circuit that prevents the movement of the shack by triggering the brake on the crane. The pipeline weld shack is a perfect example of how artificial intelligence and modern machine learning algorithms can dramatically improve safety and efficiency.